Light Seas

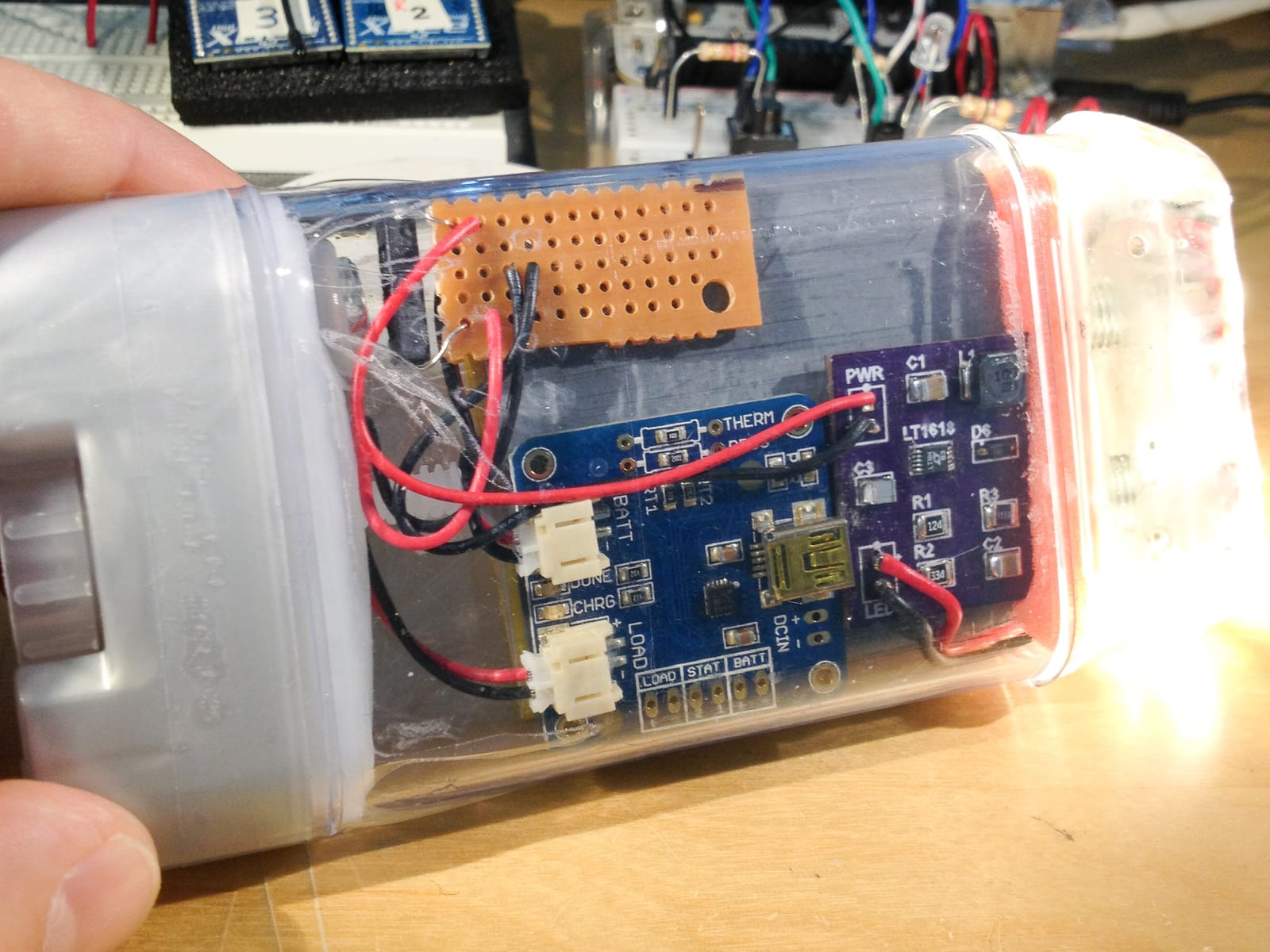

Prototype of a slimmer rechargeable SCUBA diving light

Background

As a SCUBA diver I wasn't happy with the size and bulk of dive lights. I wanted a slim dive light that could easily slip into my BCD pockets and be rechargeable via USB. Disposable batteries are bad for the environment and a pain to carry around on vacation (not to mention expensive in remote locations).

Things I Learned

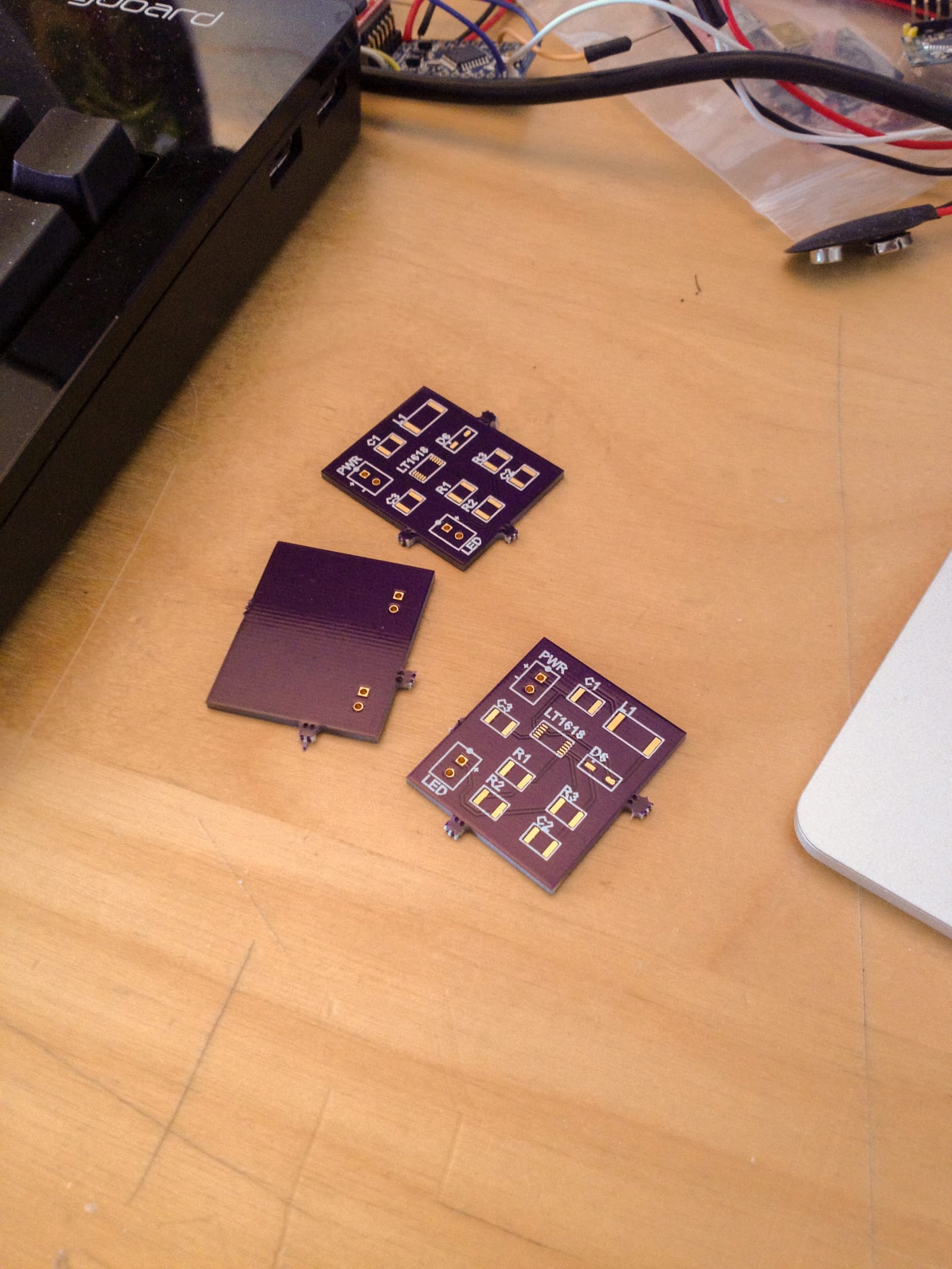

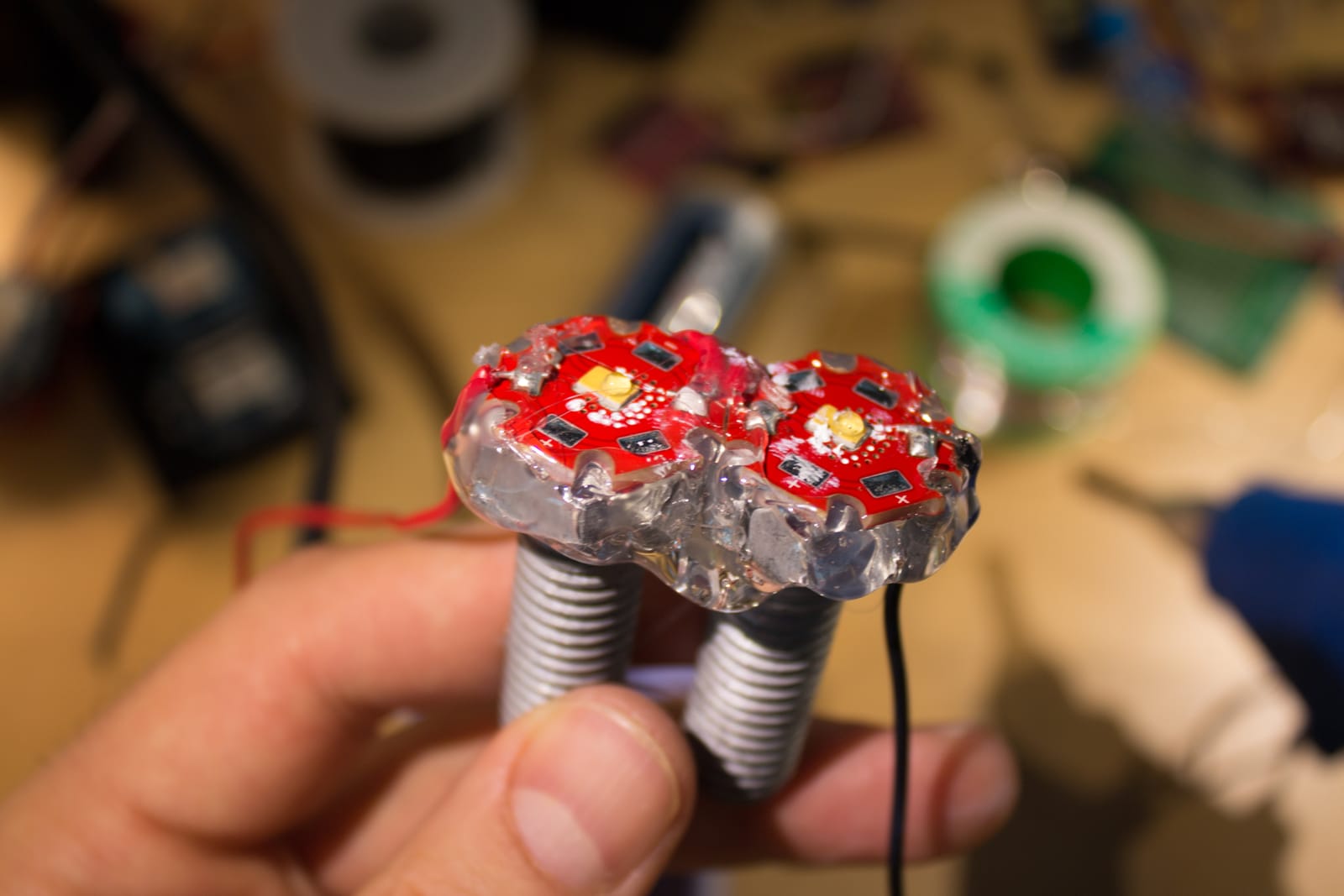

On this project I designed a circuit board based on a reference design. To help with this I used an early version of Upverter. It was just the level of complexity I needed at the time. The team there has a great product and they were very helpful in assisting me to make my design better. Through that site (at the time) I was also able to order the PCBs from the fab. I think (based on the color) that they came from OSHPark. I highly recommend OSHPark for all your low-run PCBs.

Here's the project page on Upverter.

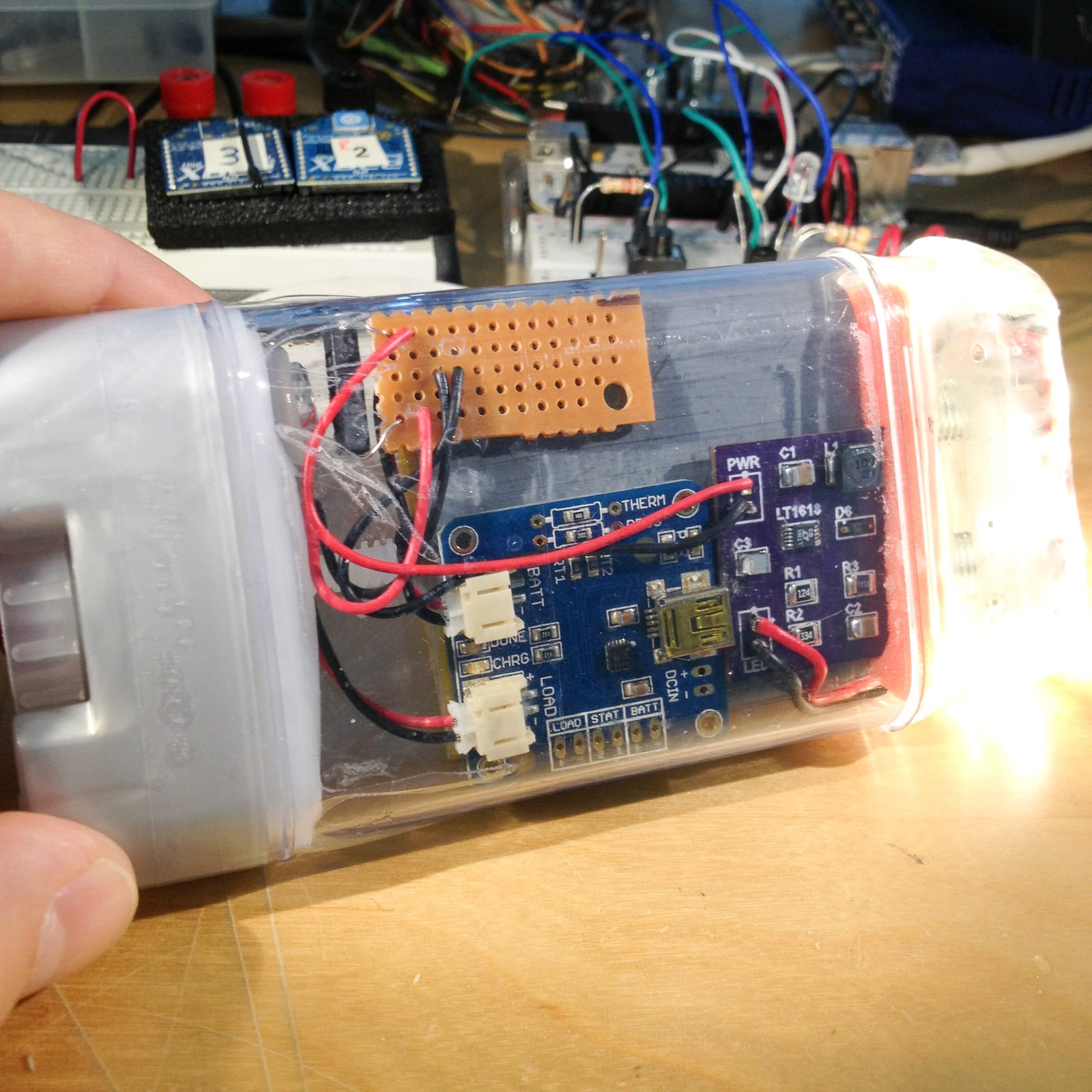

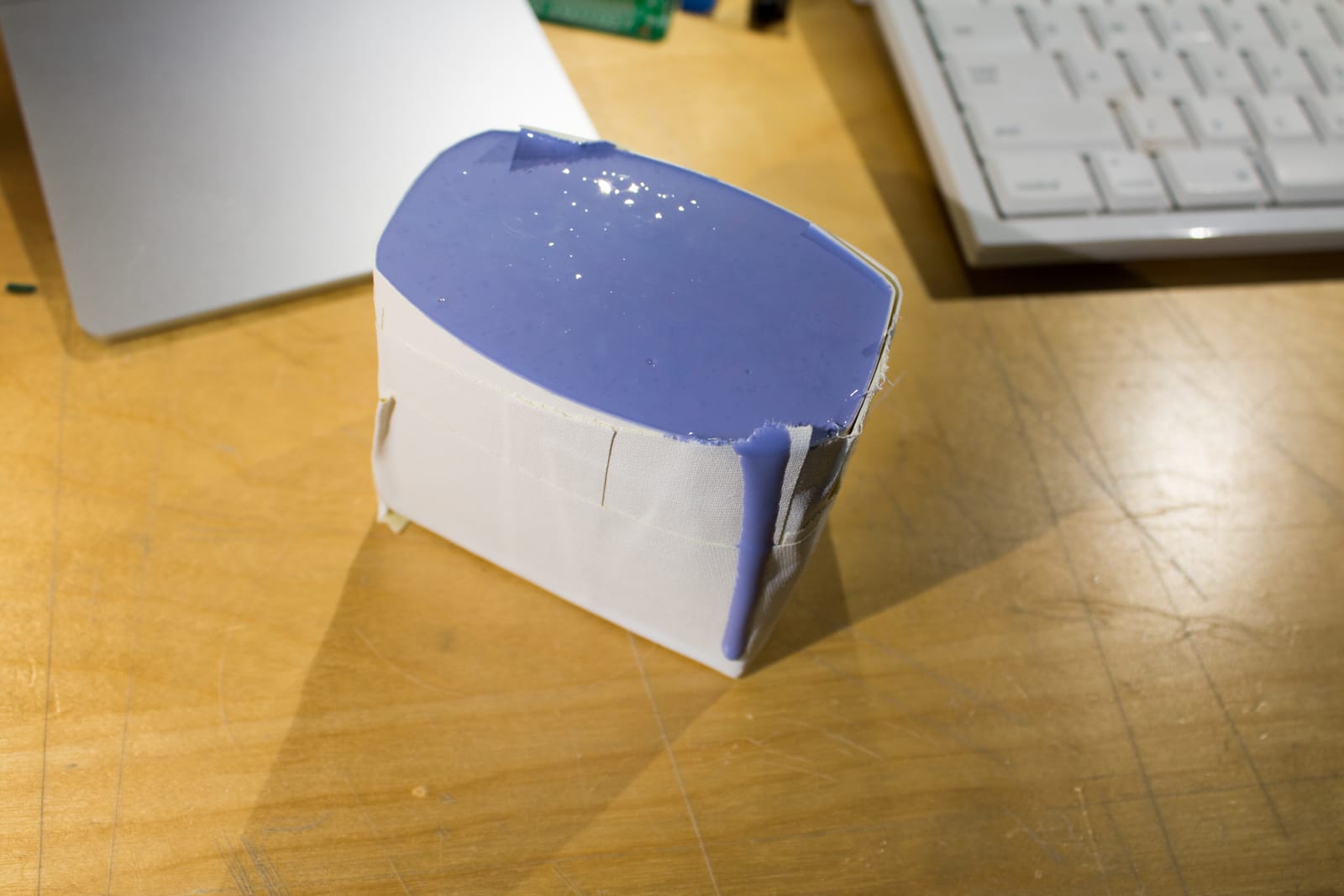

You'll notice that the enclosure is a deodorant container. Gillette Cool Wave Clear Gel to be precise. This was my go-to deodorant for a while.

Pretty funny I think. I was actually able to use the screw wheel to experiment with a magnetic reed switch as the on/off switch.

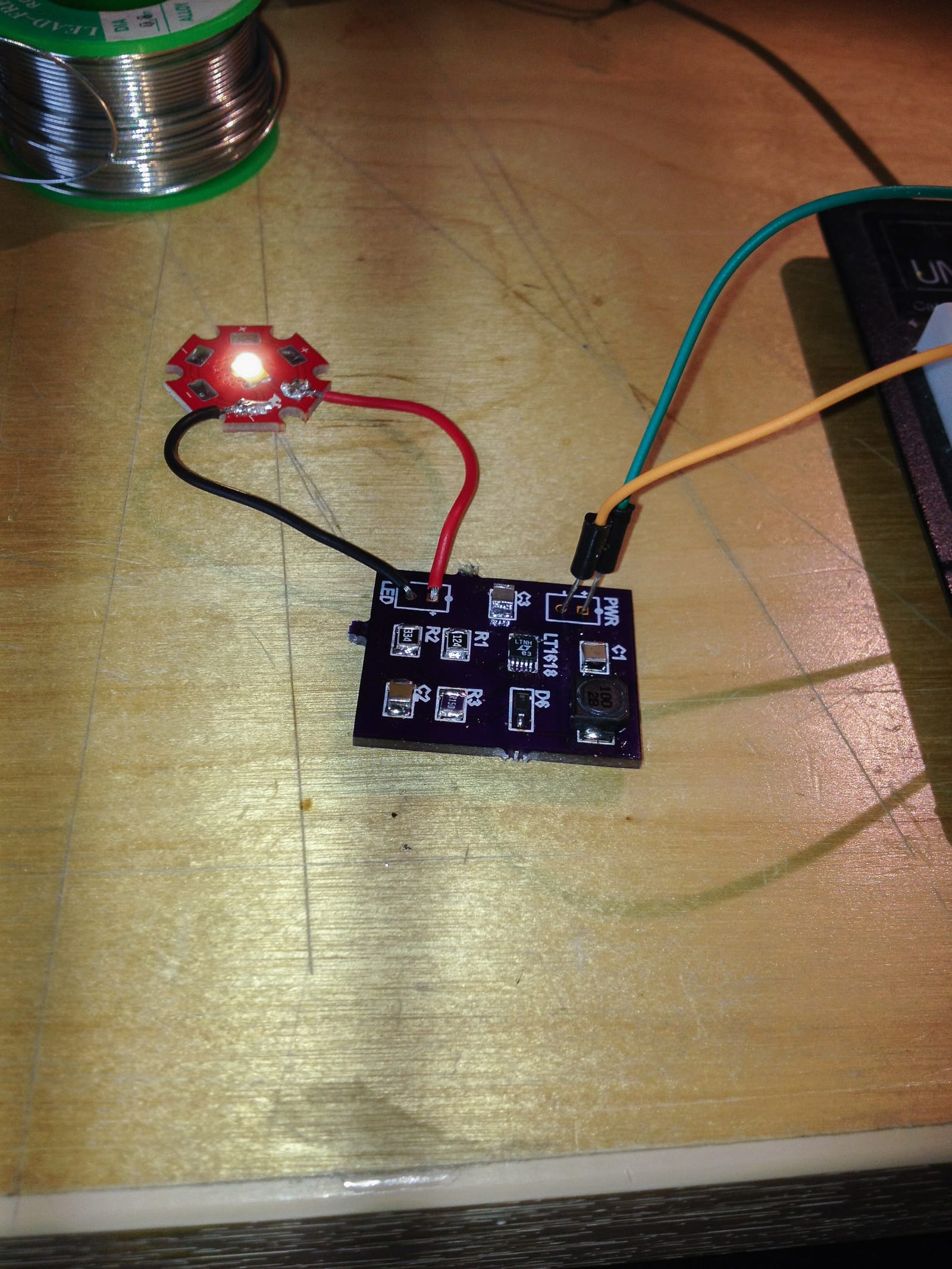

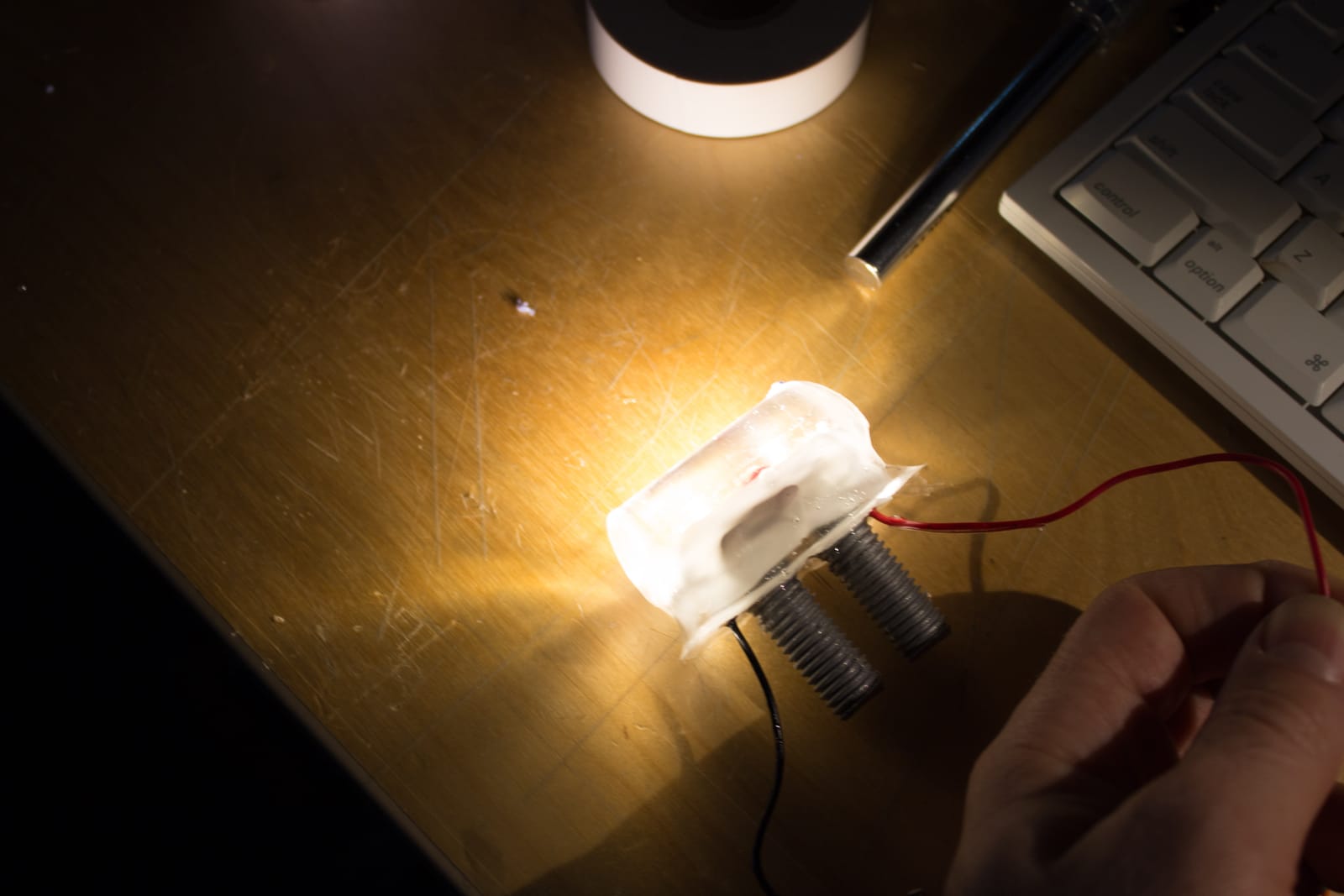

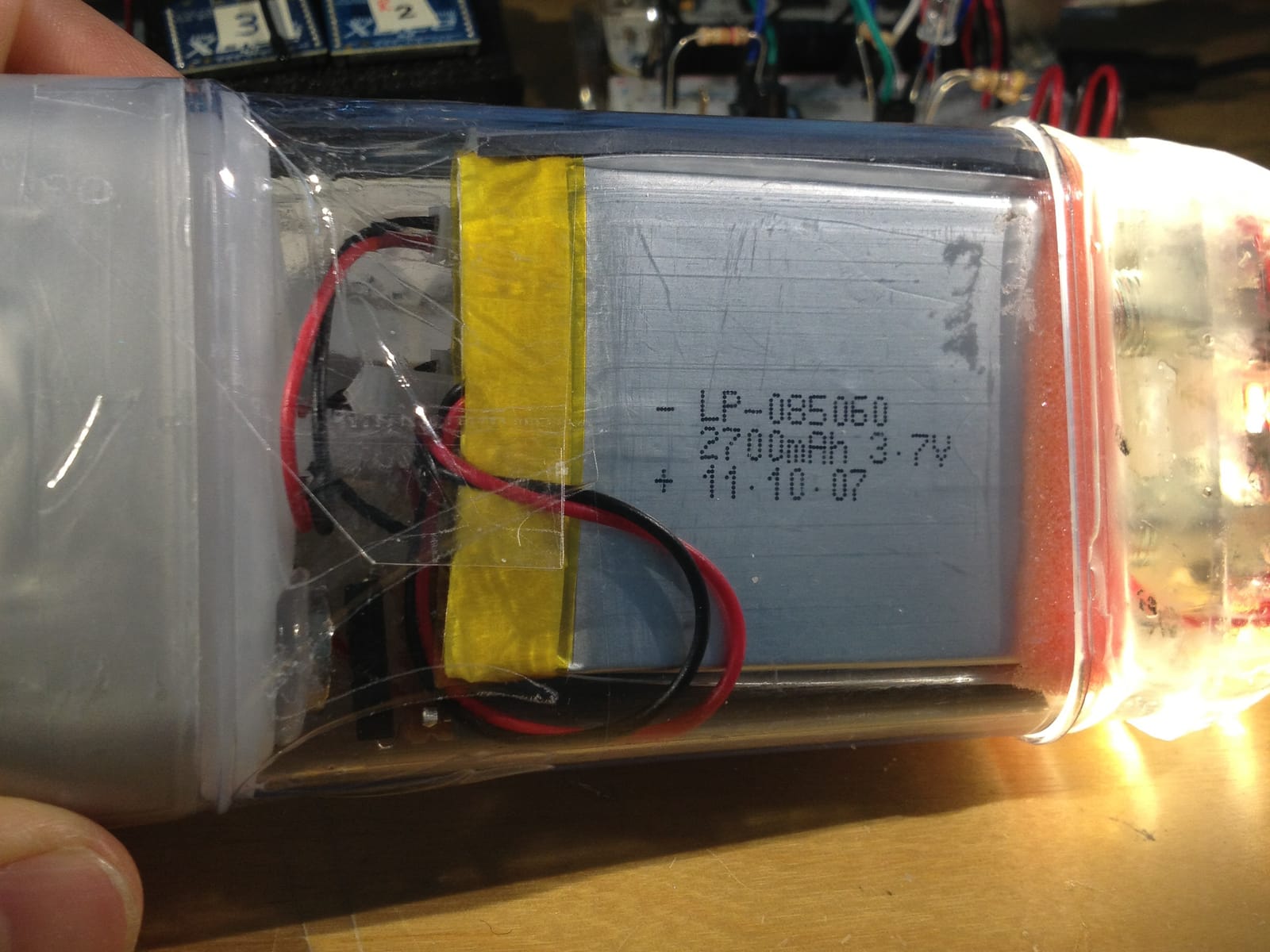

The monster-sized battery came from Adafruit along with the charge controller pack. The LEDs are 1-watt Luxeons from SparkFun. They put out a whole crap load of light. No joke. Though, probably not by today's standards...

Results

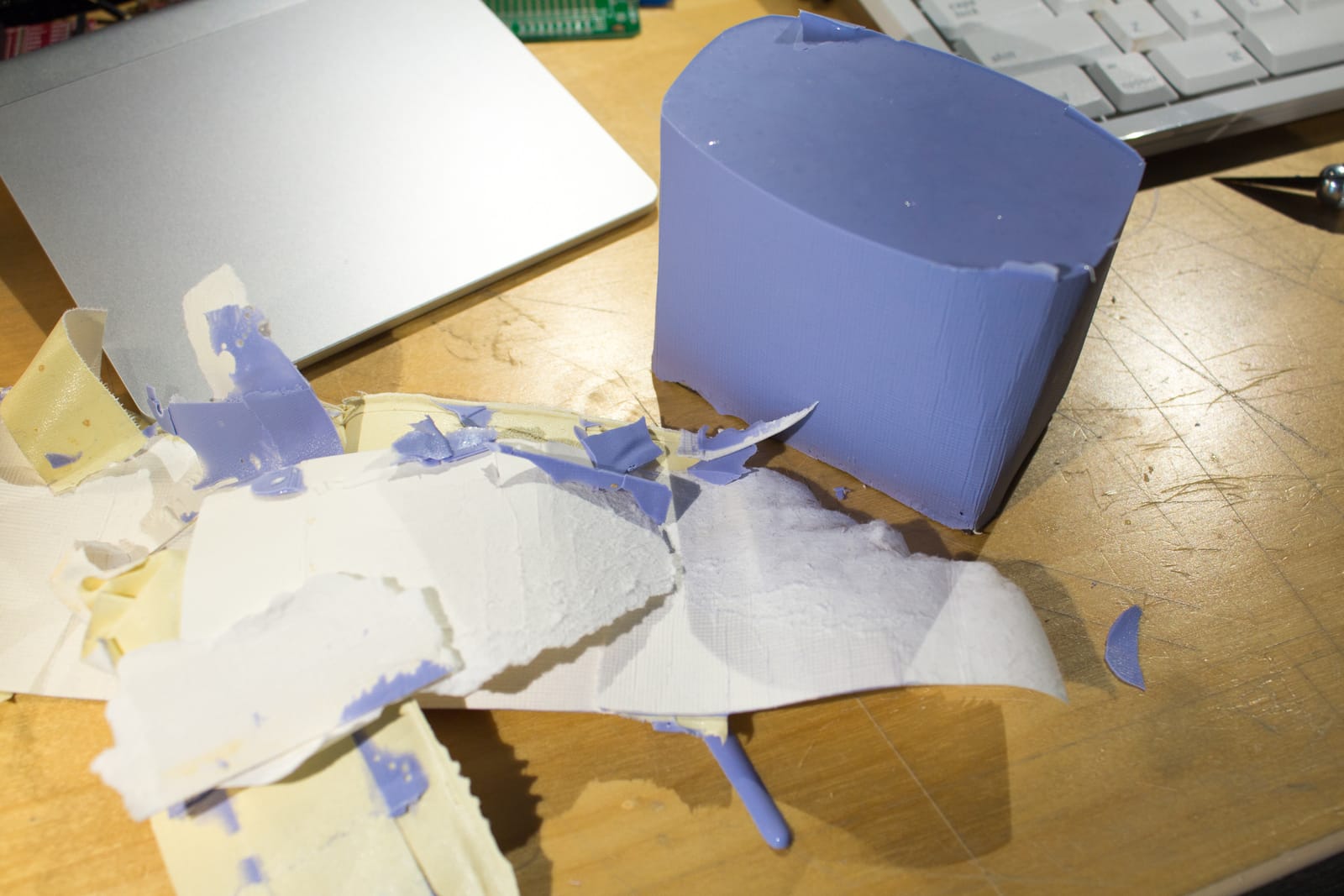

The project worked and I took it on a few non-diving trips to use as a flashlight. The epoxy resin I used to embed the LED lights started to yellow over time. That's pretty common for that material. After a year or so of moving on to other projects I eventually dismantled it for parts. As a product I would have to compete with the many other great LED dive light manufacturers out there. LED lights are pretty much the standard these days.

Assembly

PCBs from OSHPark!

Hand soldering SMD parts. A bit challenging, but the circuit works!

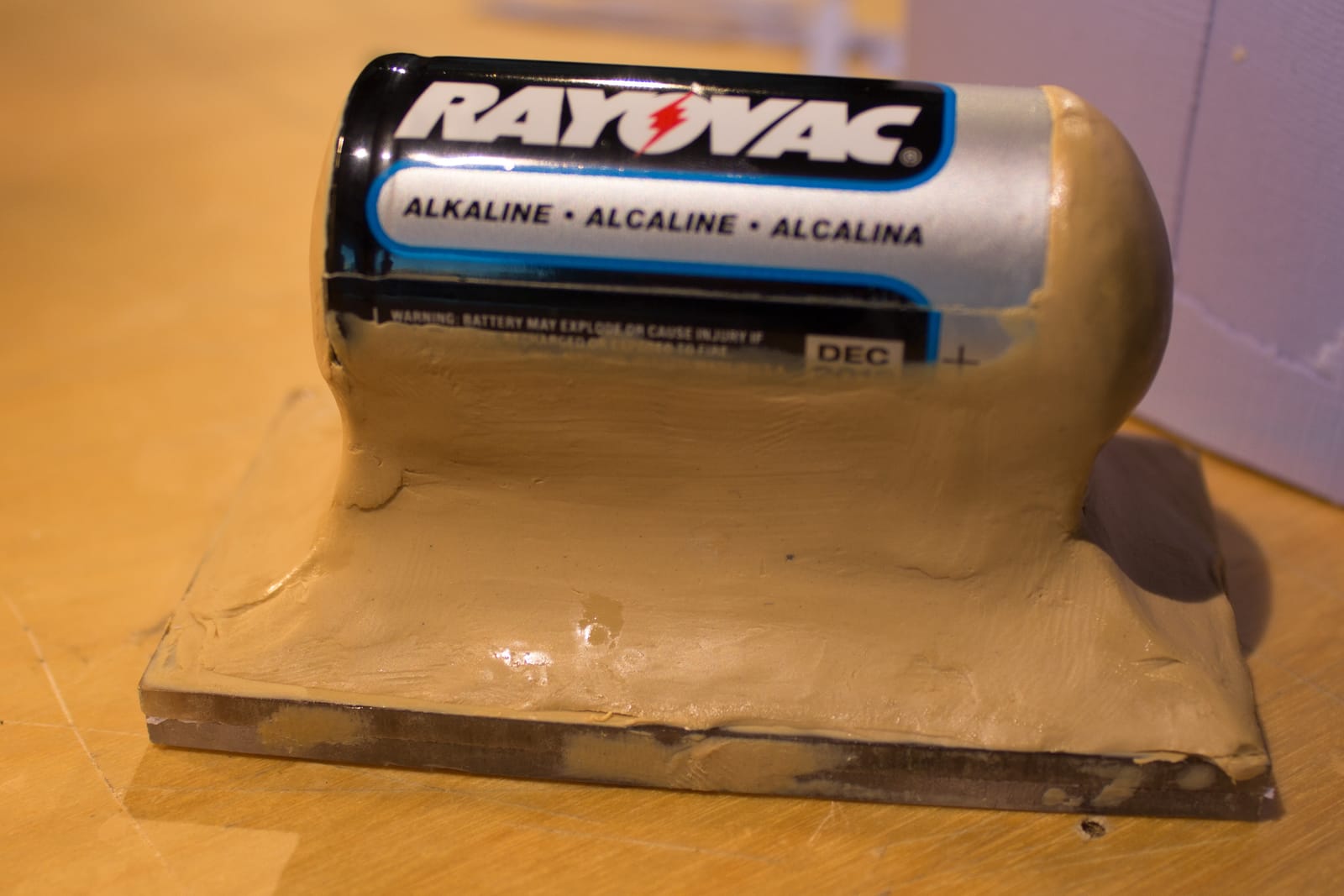

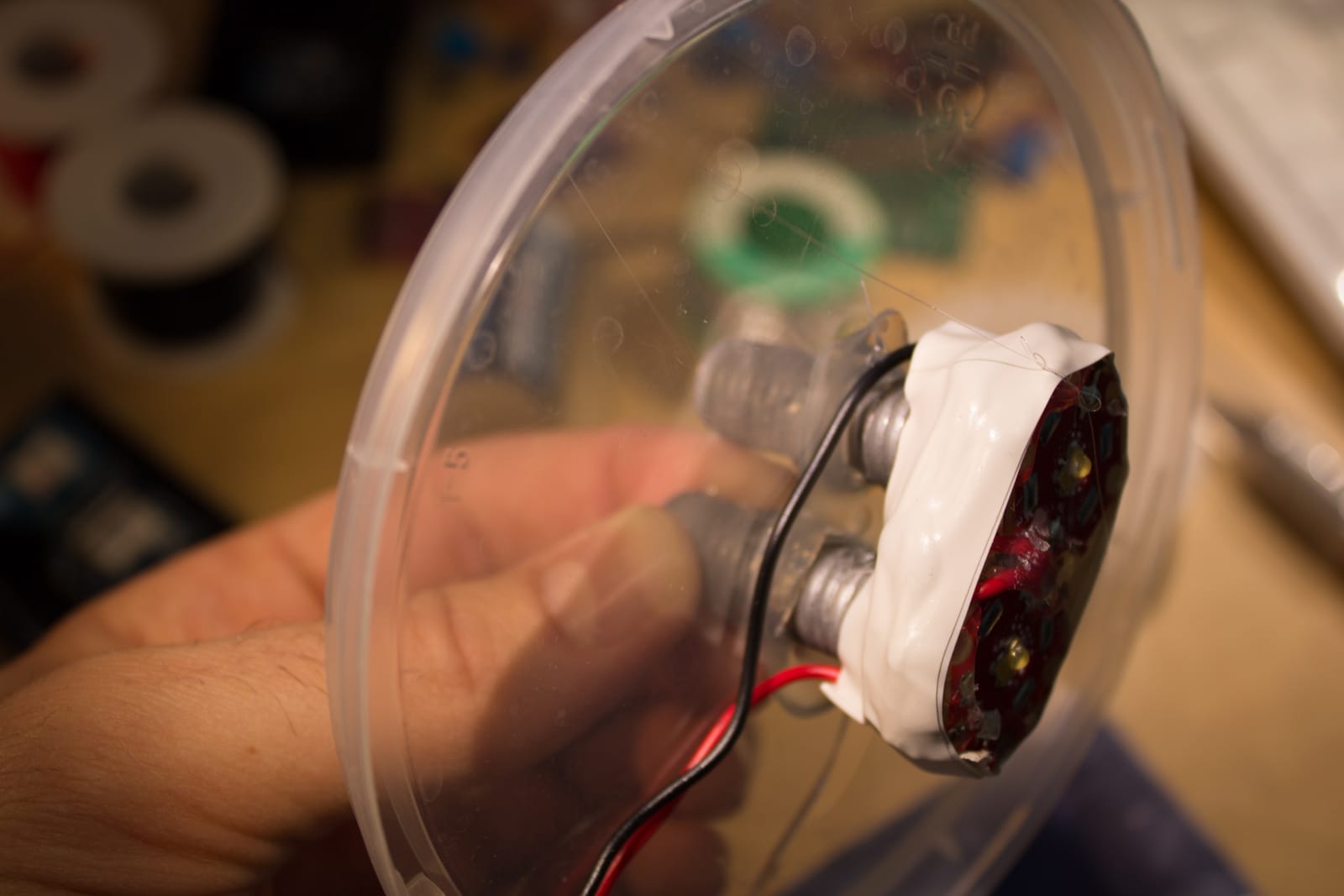

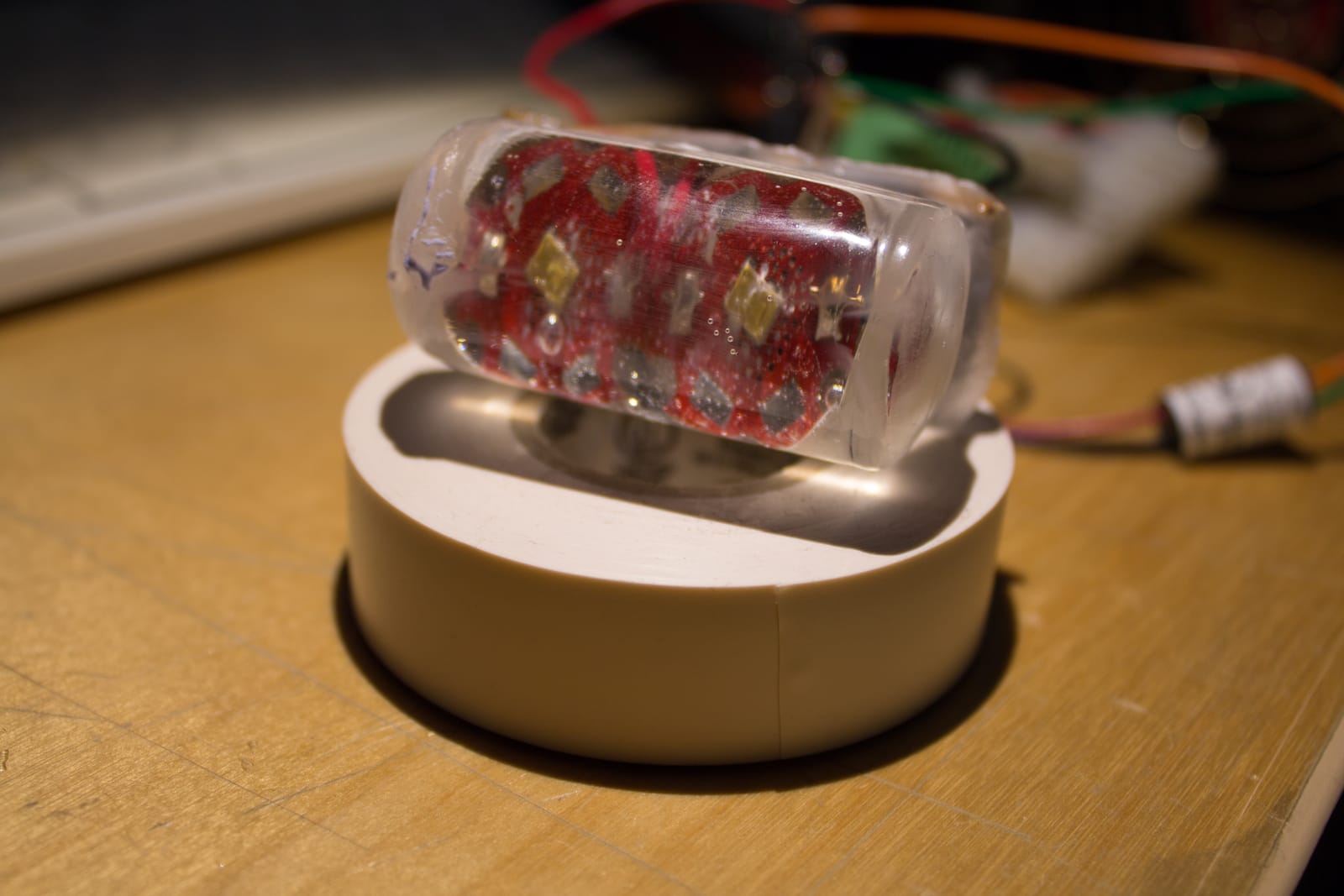

I wanted to experiment with embedding the LED lights in resin epoxy. I needed a smooth surface for the front of the lens. I had a battery lying around and it seemed pretty smooth, so I used it.

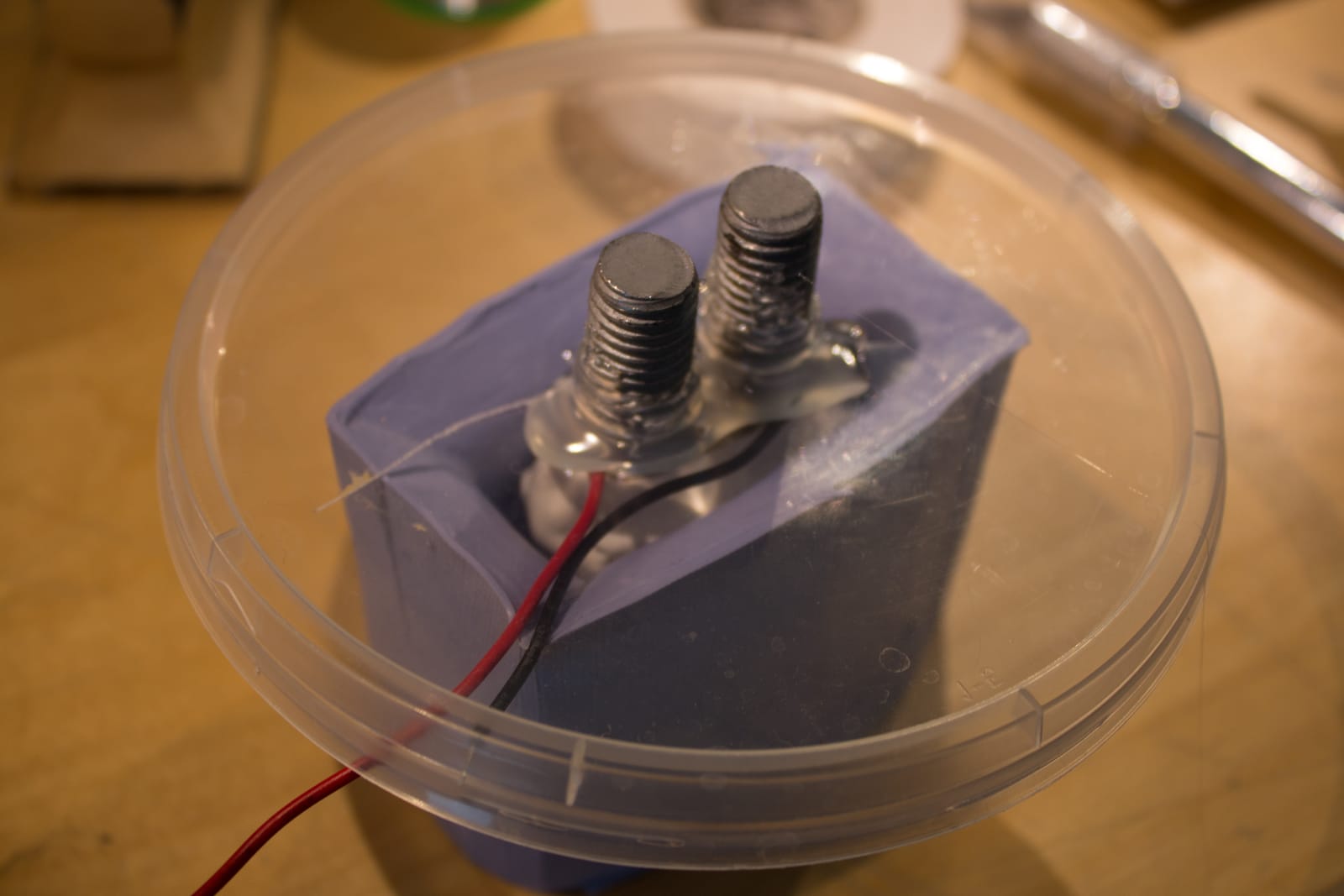

Here's the mold making.

The LEDs get pretty hot so I stuck a couple of big bolts on the back as heatsinks. Seemed like a good idea at the time.

It seems pretty smooth in there.

To keep the LEDs at the right depth in the epoxy mold I had to build a crude holder.

Like this.

After it was all cured I tested it out. Everything still works! Success?

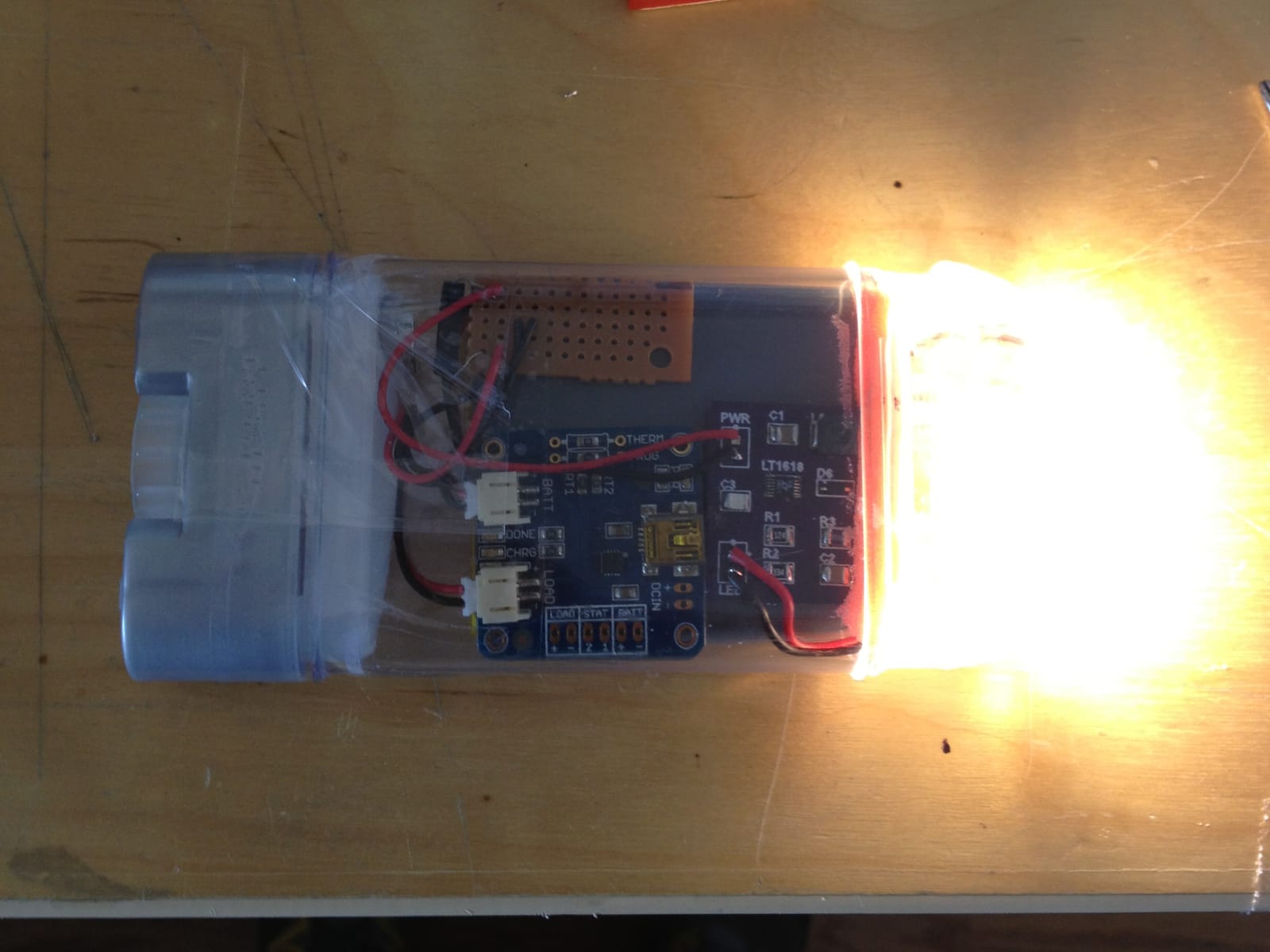

All assembled in my designer enclosure.

Testing the light.